The experts at Miracle Welding Inc. can meet nearly any welding needs, whether you require Arc welding, MIG welding, TIG welding, or other solutions. To help provide top-quality welding services, we work based on certain welding codes that facilitate uniformity and efficiency. There are many welding codes that have been developed over time, setting various requirements for testing, inspection, maintenance, and other aspects of welding.

Two common welding codes that you may encounter are AWS D1.1 and AWS 14.1. The American Welding Society (AWS) developed these specifications to provide standards for steel structural welding and various types of construction and earth-moving equipment, respectively. Here we’ll go over what these specific welding codes cover and how they apply to different welding applications.

AWS D1.1

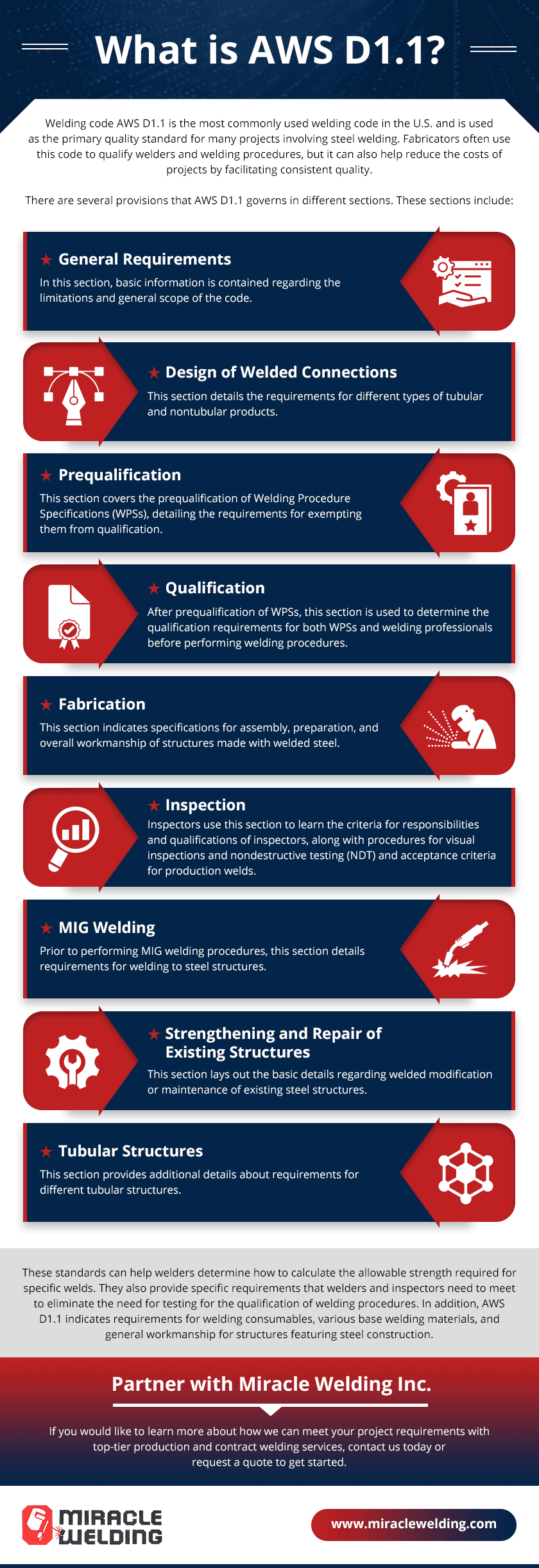

Welding code AWS D1.1 is the most commonly used welding code in the U.S. and is used as the primary quality standard for many projects involving steel welding. Fabricators often use this code to qualify welders and welding procedures, but it can also help reduce the costs of projects by facilitating consistent quality.

There are several provisions that AWS D1.1 governs in different sections. These sections include:

- General Requirements. In this section, basic information is contained regarding the limitations and general scope of the code.

- Design of Welded Connections. This section details the requirements for different types of tubular and nontubular products.

- Prequalification. This section covers the prequalification of Welding Procedure Specifications (WPSs), detailing the requirements for exempting them from qualification.

- Qualification. After prequalification of WPSs, this section is used to determine the qualification requirements for both WPSs and welding professionals before performing welding procedures.

- Fabrication. This section indicates specifications for assembly, preparation, and overall workmanship of structures made with welded steel.

- Inspection. Inspectors use this section to learn the criteria for responsibilities and qualifications of inspectors, along with procedures for visual inspections and nondestructive testing (NDT) and acceptance criteria for production welds.

- Stud Welding. Prior to performing stud welding procedures, this section details requirements for welding studs to steel structures.

- Strengthening and Repair of Existing Structures. This section lays out the basic details regarding welded modification or maintenance of existing steel structures.

- Tubular Structures. This section provides additional details about requirements for different tubular structures.

These standards can help welders determine how to calculate the allowable strength required for specific welds. They also provide specific requirements that welders and inspectors need to meet to eliminate the need for testing for the qualification of welding procedures. In addition, AWS D1.1 indicates requirements for welding consumables, various base welding materials, and general workmanship for structures featuring steel construction.

AWS D14.1

AWS D14.1 is listed as the Specification for Welding of Industrial and Mill Cranes and Other Material Handling Equipment. This code is used to specify welding requirements for manufacturing cranes for different mill, powerhouse, industrial, and nuclear facilities. It also applies to certain types of material handling equipment and machinery that are used for transporting or supporting loads.

The different provisions that AWS D14.1 specifies include the welding, producing, providing, recording, controlling, and inspecting standards for the welding of both overhead cranes and material handling equipment. In the process, this welding code helps maintain consistent quality and repairs for welding cranes and material handling systems. However, the specification doesn’t apply to crawler- or construction-type cranes, and separate standards apply to railing used in these applications under welding code AWS D15.2.

Partner with Miracle Welding Inc.

Both AWS D1.1 and AWS D14.1 apply to many welding applications across a variety of industries and facilities. These codes, along with others, can help maintain consistent quality and subsequently lower the costs of welding procedures. To provide our customers with the best results achievable, the experts at Miracle Welding Inc. adhere to these and other standards. If you would like to learn more about how we can meet your project requirements with top-tier production and contract welding services, contact us today or request a quote to get started.